|

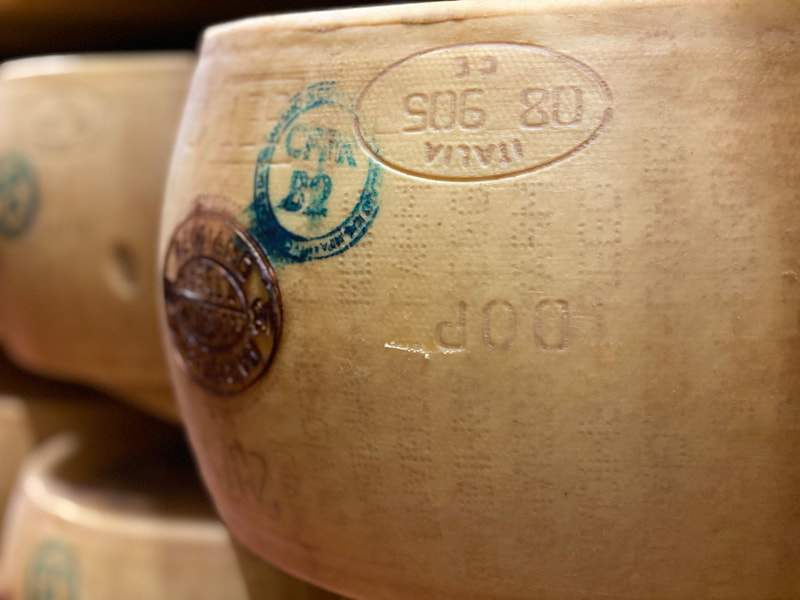

The Emilia-Romagna region is often considered the foodie capital of Italy. It is home to authentic Parmigiano-Reggiano cheese, traditional balsamic vinegar, excellent charcuterie and truffles. It is also the birthplace of Bolognese sauce and mortadella (which is also known as bologna). On my “not so recent” trip to Italy, I decided to take a Modena food tour. I read reviews that the “Italian Days Food Experience” is an epic Modena food tour. And indeed, there was so much to eat, drink and learn while exploring Parmigiano-Reggiano cheese, balsamic vinegar and prosciutto factories! Parmigiano-Reggiano Factory TourItalian Days Food and Wine Tours conveniently picked me up right from my apartment in the center of Bologna, Colonne Apartments. Pick up time is 7am sharp because it takes an hour to drive to Modena and Parmigiano-Reggiano production is only done in the early morning. We were only nine in the tour - some came from the US and Australia. It was a very nice group. We were met at our first stop of the day by our host and guide, Francesco, who started the tour proper with his humorous and rambunctious spiel, emphasizing DOP to the nth degree. Not only was this guy upbeat, he was a clever marketer too. Prior to entering the plant, we were given disposable lab coats and shoe covers. And yes, a hot cup of espresso. What is a DOP? DOP stands for “Denominazione di Origine Protetta” (in English, is Protected Designation of Origin). For instance, Parmigiano-Reggiano cheese is a DOP product because it is produced in a restricted area, raw materials must come from the production area, and all producers make it the same way. From L to R: the cheese consortium factory; Francesco (our host and guide); covering up before the tour proper. Once we get the very basic knowledge down, we learned that making Parmigiano-Reggiano is no small feat. It takes a lot of work and special care and knowledge. Authentic Parmigiano-Reggiano cheese consists of just three ingredients - milk, salt and rennet (to coagulate the cheese). The territory of production is within the Province of Parma, Reggio Emilia, Modena, Bologna (west of the Reno river) in the Emilia-Romagna, and Mantua (East of the Po river) in Lombardy. Our Modena food tour of Parmigiano-Reggiano began in the order of steps it takes to make a wheel of cheese. The first one was a large room with copper vats, which cooks the milk that will turn into cheese. Cow milk (of the evening before) is mixed to the morning milk, after being partially skimmed. The rennet initiates the creation of the curd, which is then broken and heated at 35 degrees Celsius - photos below. (See...I took this food tour seriously....I have it all in my iPhone’s Notes). The cooked grains deposit at the bottom of the vat forming a big mass of cheese. The mass is then lifted out of the boiler and cut in half. Each half is wrapped in a linen cloth. One large vat will make only two large Parmigiano wheels - only two! One whole mass of curd weighs about 90 kgs. From L to R: that’s one big mass of cheese; cutting the curd in half From L to R: lifting the curds from the vats and moving it to another room . These curds will be placed in plastic moulds, where it will rest for three days, and form the shape of the wheel. After three days in the plastic mold, the cheese is then put into a stainless steel, round form that is pulled tight with a spring-powered buckle so the cheese retains its wheel shape. After two days, the buckle is released and a plastic belt imprinted numerous times with the words “Parmigiano Reggiano” name, the plant’s number, and month and year of production is put around the cheese and the metal form is buckled tight again. After a day or two, once the wheel has been imprinted with the label, it is moved to the brining room to absorb salt for one month. That’s actually our tour guide, Francesco, holding the plastic belt imprinted with the DOP details and demonstrating how it is placed in the mold. (I had no idea what happened to the photo when I uploaded it....aargh.) Gleeful in a a rom full of 3 to 4 day old Reggianos. THE brining room. Finally, there’s my friend Francesco. After a month of “salt bathing”, the cheese wheels are moved to the aging room in the plant for 12 months. The cheese is placed on wooden shelves that can be 24 cheeses high...yes, I counted. And during this time, every cheese wheel are turned every two weeks to prevent molds. AND, this is important, each cheese and the shelf underneath is cleaned manually or robotically (yes, they have machines to do that) every 7 days. After 12 months, representative from the Consorzio Parmigiano-Reggiano inspects every wheel. (I had to make sure I wrote it down, because, you know that’s “every wheel”). The “Cheese Masters”, as they call them, bangs the cheese wheel and listen for the correct sound. Wheels that passed the test are heat stamped with the DOP and the consortium’s logo. What happens to the cheese wheels that do not pass THE test? Well, they were simply thrown away. Just like that. Why? Because they do not want to provide consumers with “low quality” Parmigiano-Reggiano. We were then taken to the storage facility, the “cheese bank”, which impressively houses thousands of wheels of cheese. (Ok, be still my heart. We can do this...pagsubok lang ito.) Our guide, Francesco, joked that if you are thief, don’t rob a bank in Italy because they’re broke. Instead, rob a Parmigiano-Reggiano cheese factory! Each wheel of cheese costs around USD620. The factory we toured had around USD28 million worth of cheese...!!! (Hmmmm....Cheese instead of gold bullions....why not? ) Rows and rows of 12 to to 18 month old cheese wheels From L to R: this “robot” machine cleans, and turns, the wheels every seven days. And that was me, showing my love to the KING of cheeses. I am in love. At last...fully aged...ready to eat...cheese wheels. BEAUTIFUL, GOLDEN, and DELICIOUS PARMIGIANO- REGGIANO. And my knees are weak....!!! Someone....can someone...please help me get out of this cheese coma. Anyone? After all is said and done - from milking the cows, processing, and aging it 12 months and longer, to final inspections — there is the birth of the KING OF CHEESE. True Parmigiano-Reggiano cheese takes time and care and results in a product of excellent quality. Top quality also means a higher price. And it never ends up in a can. :-) After touring the factory, we were driven to a nearby farm...which is liteally a 2 minute drive from the consortium...to enjoy generous helpings of Parmigiano-Reggiano cheese, breads, and Lambrusco wine. The cheeses we enjoyed were aged 13 month and 25 month old. I preferred the latter because it had a lot of flavor - sharp, complex fruity/nutty/savory taste - and a nice slightly gritty texture. The younger cheese was more soft and not as bold. As delicious as the cheeses were, we couldn’t finish the large chunks they put out because it was simply more cheese than we could eat...!!! It’s difficult to imagine ever eating “Parmesan” (aaaahhh...the one you buy in the green box) cheese again after that experience. From L to R: Some of the cheese we had at the farm. The group enjoying a breakfast of cheese and Lambrusco wine. I also learned that the different kinds of hay the cows eat can affect the flavor of the cheese. And the type of cow also has a huge effect for taste and texture, therefore, the consortium uses two different type of cows. Since the farm has been passed down in the family for generations, Francesco told us how they have had trial and errors figuring out the right types of cows to have and what hay they need to eat. It is all in the details...!!! Stacks of hay and inside one of the barns in the farm. Haaah....farm life. We finished the first food tour around 10 am and what a way to start the day.. I learned and saw so much behind the scenes. For me....it was another culinary dream...achieved.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Archives

May 2020

Lea DalawisA corporate employee by profession, a home cook, an avid foodie, an obsessive cooking books collector, a wanna-be-food photographer, a budding Writer, a DIY fan, and a Traveller. Categories |

RSS Feed

RSS Feed